Necessary Guide to Searching For Reliable Commercial Refrigerator Repair Solutions

Necessary Guide to Searching For Reliable Commercial Refrigerator Repair Solutions

Blog Article

Taking Full Advantage Of Effectiveness: Commercial Refrigeration Repair Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

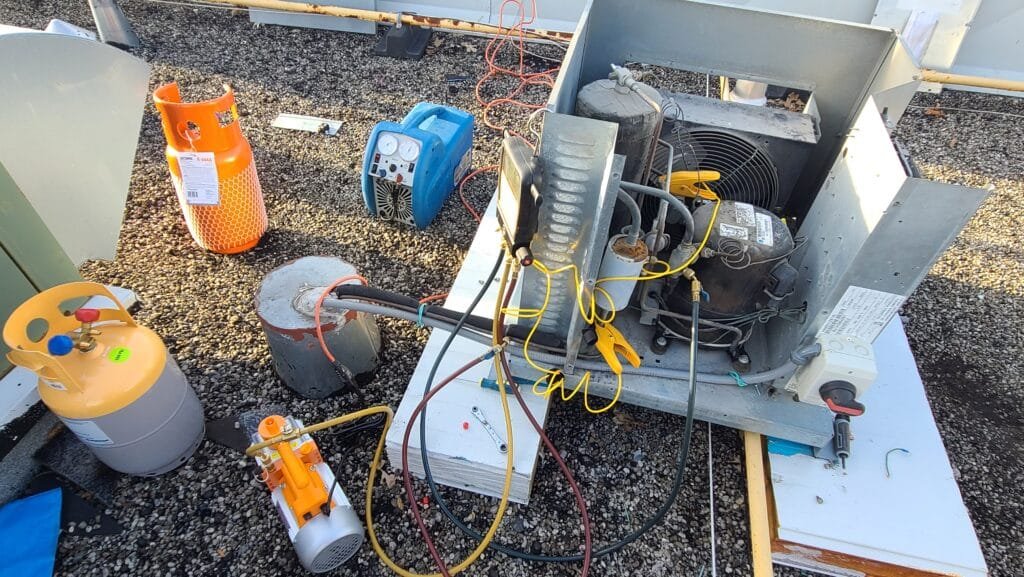

To successfully evaluate the efficiency of an industrial refrigeration system, it is important to carry out extensive analyses of its crucial parts and functional parameters. The initial step in evaluating system efficiency is analyzing the functionality of the compressor.

Monitoring refrigerant degrees and stress is also crucial in assessing system performance. Reduced refrigerant levels or uncommon pressures can suggest leaks or malfunctioning components that require prompt focus to protect against system failures and expensive repairs. By systematically evaluating these key elements and functional criteria, organizations can ensure their commercial refrigeration systems operate at peak efficiency levels, decreasing downtime and taking full advantage of power performance.

Carrying Out Preventative Maintenance Steps

Examining the performance of a business refrigeration system supplies valuable understandings that can notify the implementation of preventative upkeep steps crucial for maintaining optimal capability and durability. Preventative upkeep is a proactive strategy aimed at determining and dealing with possible issues prior to they rise into expensive troubles that interrupt operations. By developing a normal maintenance schedule, refrigeration systems can run successfully, decreasing power consumption and minimizing the threat of unexpected malfunctions. Secret preventative maintenance steps consist of cleansing and evaluating condenser coils, examining refrigerant degrees, guaranteeing correct airflow, and adjusting temperature level controls. In addition, keeping an eye on temperature and humidity degrees, inspecting door seals, and addressing any type of uncommon noises or odors quickly are vital steps in preventative upkeep. Applying these actions not only prolongs the life-span of the equipment but also enhances food safety by preserving consistent storage space temperatures. Eventually, buying preventative maintenance procedures is a cost-effective strategy that aids organizations prevent pricey repair work and downtime, making sure trustworthy and continual refrigeration system performance.

Identifying Common Refrigeration Issues

One of the essential facets in maintaining commercial refrigeration systems is without delay determining typical issues that may develop during their operation. One common issue is poor cooling, often brought on by unclean condenser coils or a malfunctioning compressor. Normal cleaning of the condenser coils and ensuring correct ventilation around the unit can assist prevent this problem. Another common problem is refrigerant leakages, which can bring about ineffective air conditioning and potential ecological dangers. Keeping track of cooling agent degrees and carrying out regular inspections for leakages can assist minimize this problem. Additionally, defective gaskets on doors, causing air leaks, can cause the refrigeration system to work more challenging to keep the preferred temperature. Normal examination Clicking Here and substitute of harmed gaskets investigate this site are necessary to avoid energy waste. Uncommon sounds such as knocking, clanking, or hissing could suggest underlying mechanical issues that require instant focus to avoid further damage. By promptly identifying and attending to these common refrigeration concerns, organizations can ensure the efficient operation of their systems and lessen pricey repair work.

Using Energy-Efficient Repair Service Methods

When thinking about commercial refrigeration repair work, executing energy-efficient methods is extremely important to optimizing the system's performance and reducing functional costs. One of the essential techniques in attaining energy performance is guaranteeing that the refrigeration system is correctly preserved. Normal upkeep, such as cleaning condenser coils, looking for cooling agent leaks, and calibrating temperature setups, can dramatically enhance energy effectiveness.

One more energy-efficient repair technique is upgrading to high-efficiency parts - commercial refrigeration repair. By changing older, much less effective get rid of energy-efficient choices, such as ECM fan motors or LED lighting, companies can minimize power consumption and reduced energy costs. In addition, setting up programmable thermostats and energy monitoring click here for more info systems can aid regulate temperature levels extra efficiently, avoiding unnecessary power use

In addition, enhancing the system's insulation and securing any leaks can likewise add to energy financial savings. Correct insulation aids preserve consistent temperatures within the refrigeration unit, reducing the work on the system and boosting overall effectiveness. By incorporating these energy-efficient repair work techniques, organizations can not only minimize their environmental influence but also accomplish long-lasting cost savings.

Optimizing Refrigeration System Life-span

To ensure the durability and optimum performance of commercial refrigeration systems, preserving energy-efficient repair work practices is necessary, with an emphasis now shifting in the direction of taking full advantage of the refrigeration system lifespan. Maximizing the life expectancy of a refrigeration system entails aggressive maintenance, prompt fixings, and adherence to maker standards.

Furthermore, spending in high-grade components and parts throughout fixings and substitutes can improve the longevity of the refrigeration system. By prioritizing aggressive upkeep and using high quality elements, companies can optimize the life-span of their commercial refrigeration systems, eventually decreasing downtime and functional costs.

Final Thought

Finally, by on a regular basis analyzing refrigeration system efficiency, implementing preventative upkeep measures, recognizing common refrigeration problems, utilizing energy-efficient fixing methods, and maximizing the system's life expectancy, services can take full advantage of performance and reduce costs related to industrial refrigeration repair work. These cost-efficient options help to make sure that refrigeration systems operate at peak efficiency, ultimately leading to increased efficiency and profitability for companies in the lengthy run.

When thinking about industrial refrigeration fixing, implementing energy-efficient methods is extremely important to optimizing the system's performance and decreasing operational expenses.To guarantee the durability and optimum efficiency of business refrigeration systems, maintaining energy-efficient repair practices is essential, with a focus now moving in the direction of maximizing the refrigeration system lifespan. Optimizing the life-span of a refrigeration system involves proactive maintenance, timely repairs, and adherence to manufacturer guidelines.

Report this page